BIM Coordination Process Explained (Clash Detection & Resolution Workflow)

The BIM Coordination Process is the backbone of modern construction delivery across Australia’s commercial, healthcare, data centre, defence, and infrastructure sectors. On Tier 1 and Tier 2 projects, uncoordinated MEP systems no longer result in minor inconvenience — they trigger structural rework, programme delays, procurement disruption, and contractual exposure.

Australian projects operate under strict NCC compliance, tight ceiling voids, seismic and fire constraints, and increasingly aggressive construction programmes. In this environment, structured clash detection and model-based coordination are not optional. They are risk mitigation mechanisms.

This article provides a complete technical breakdown of the BIM Coordination Process, including clash detection workflow, model federation standards, responsibility matrices, revision cycles, LOD alignment, and ISO 19650 BIM Australia compliance.

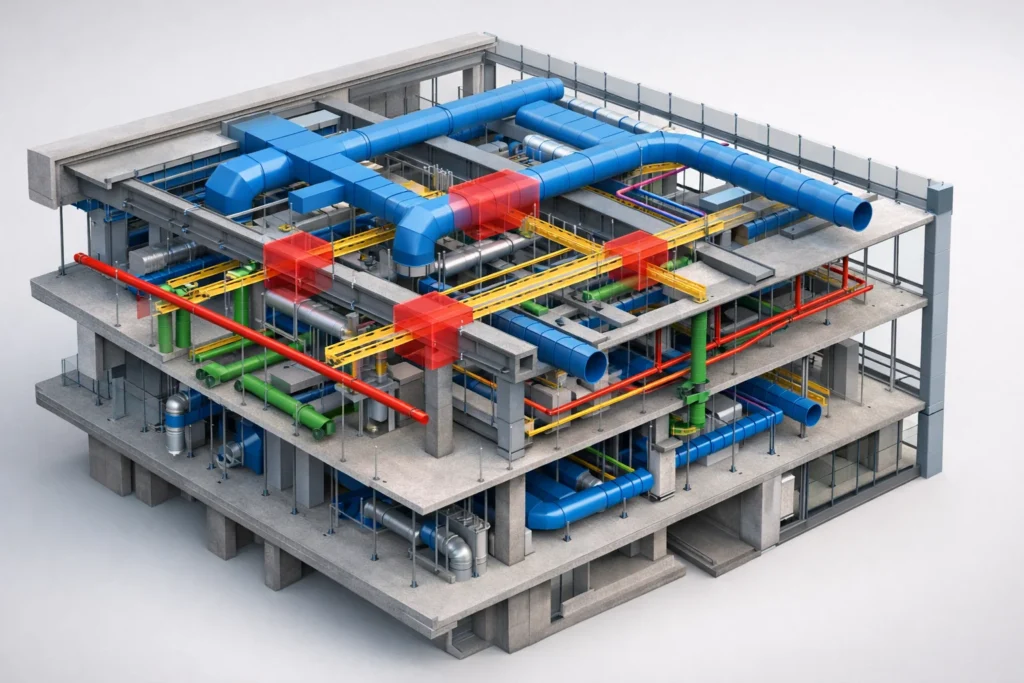

What Is the BIM Coordination Process?

The BIM Coordination Process is a structured methodology used to integrate discipline models into a federated environment, detect and resolve spatial and clearance conflicts, and achieve coordinated sign-off prior to construction.

It extends far beyond running Navisworks clash detection. It includes:

- Model quality control validation

- Shared coordinate compliance

- Federated model governance

- Clash detection configuration

- Clash grouping and prioritisation

- Structured coordination meetings

- Responsibility assignment

- Revision tracking cycles

- Formal coordination approval

When aligned with ISO 19650 BIM Australia principles, it ensures consistent information management and controlled model exchange across all consultants and subcontractors.

Why the BIM Coordination Process Is Critical in Australian Projects

Australian commercial and infrastructure builds face specific coordination pressures:

- Post-tension slab constraints

- Dense services in reduced ceiling voids

- Fire separation and compartmentation rules

- Seismic bracing requirements

- Prefabrication-driven installation sequences

Without structured MEP clash detection, issues surface on site — not in the model. Once construction begins, every clash becomes a variation, delay, or redesign event.

Step-by-Step BIM Coordination Process

1. Discipline Model Preparation

Effective coordination begins with model integrity. Each discipline model must comply with agreed:

- LOD requirements (typically LOD 350 minimum)

- Shared coordinate systems

- Naming conventions

- System classification standards

- Revision control procedures

Model audits are conducted to remove duplicate geometry, over-modelled content, and embedded drafting artefacts. Poor model hygiene produces false clashes and wastes coordination cycles.

2. Model Federation

Federation combines mechanical, electrical, hydraulic, fire, structural, and architectural models into a unified coordination environment.

Typically performed in:

- Navisworks Manage

- Revizto

- Autodesk Construction Cloud

- Solibri

Correct origin alignment and coordinate locking are critical. Even minor coordinate shifts invalidate clash detection accuracy.

3. Clash Detection Setup

Clash detection configuration determines coordination quality. Tests are defined per trade interface using structured clash matrices.

Clash categories include:

- Hard clashes – physical intersection

- Soft clashes – encroachment into reserved zones

- Clearance clashes – maintenance/access violations

Tolerance levels are defined to eliminate false positives while maintaining compliance accuracy.

4. Running Navisworks Clash Detection

Navisworks clash detection tests are executed zone-by-zone:

- Basements

- Typical floors

- Plant rooms

- Risers

- Roof spaces

Raw outputs are exported and structured before presentation.

5. Clash Grouping & Prioritisation

Thousands of raw clashes are grouped by:

- Location

- Trade interface

- System type

- Severity

Priority classification:

- High: Structural impact or major reroute

- Medium: System coordination required

- Low: Minor adjustment

This stage transforms data into actionable engineering decisions.

6. BIM Coordination Meeting Workflow

The BIM coordination meeting workflow follows a structured format:

- Review high-priority grouped clashes

- Confirm design intent

- Agree resolution strategy

- Assign responsibility

- Record action register

Only validated clashes are discussed. Discipline and efficiency are essential.

7. Responsibility Matrix & Clash Assignment

A formal Responsibility Assignment Matrix (RAM) is maintained. Each clash is allocated to a lead trade based on installation hierarchy and system ownership.

Without clear accountability, clash resolution stalls across cycles.

8. Model Revision Cycle

Following meetings:

- Trades revise models

- Updated models are reissued

- Federation is updated

- Clash tests rerun

This iterative BIM clash resolution loop continues until acceptable tolerances are achieved.

9. Sign-Off & Coordination Approval

Coordination sign-off confirms:

- High and medium clashes resolved

- Clearance compliance achieved

- All trades formally approve

This documentation forms part of contractual protection and construction assurance.

Hard vs Soft vs Clearance Clashes Explained

Hard Clash: Duct passing through structural beam.

Soft Clash: Cable tray intruding into fire-rated zone.

Clearance Clash: Valve positioned too close to wall for servicing.

Clearance clashes are frequently underestimated but represent high operational risk.

LOD Requirements for Effective Coordination

- LOD 200: Concept level geometry

- LOD 300: Accurate dimensions

- LOD 350: Includes interfaces and supports

- LOD 400: Fabrication detail

- LOD 500: As-built verification

For reliable MEP clash detection, LOD 350 minimum is required.

Traditional 2D Coordination vs BIM Coordination

| Aspect | 2D Coordination | BIM Coordination |

|---|---|---|

| Clash Detection | Manual overlay | Automated rule-based detection |

| Risk Exposure | High | Controlled and traceable |

| Revision Tracking | Difficult | Structured digital history |

| Cost Impact | Reactive rework | Pre-construction resolution |

Common BIM Coordination Mistakes

- Incorrect shared coordinates

- Undefined clash tolerances

- Over-modelled unnecessary detail

- No structured meeting workflow

- Ignoring maintenance clearance

- Weak revision tracking

Real-World Australian Commercial Example

On a Melbourne CBD office development, initial federation produced over 3,500 clashes across mechanical, electrical, hydraulic, and structural trades.

Through structured clash detection workflow and disciplined coordination cycles:

- 85% resolved within three iterations

- Major slab penetrations coordinated before concrete pour

- Prefabrication packages issued without redesign

The result was reduced site rework and predictable installation sequencing.

Risk Mitigation & Cost Control Benefits

- Reduced RFIs

- Improved procurement certainty

- Minimised structural rework

- Safer installation sequencing

- Lower contractual dispute risk

FAQ – BIM Coordination Process

What is the BIM Coordination Process in construction?

It is a structured digital workflow for federating discipline models, detecting clashes, assigning responsibility, and achieving coordinated sign-off before construction.

How does Navisworks clash detection work?

It runs automated spatial tests between model elements based on predefined rules, tolerances, and trade interfaces.

What LOD is required for MEP coordination?

LOD 350 minimum is required to capture penetrations, supports, and system interfaces.

What are clearance clashes?

Clearance clashes occur when required maintenance or access space around equipment is violated.

How often should coordination meetings occur?

Weekly sessions are standard on Tier 1 Australian projects.

How does ISO 19650 apply in Australia?

It governs structured information management, naming, revision control, and model exchange procedures.

Conclusion: BIM Coordination Process as a Risk Management Framework

The BIM Coordination Process is not simply the use of clash detection software. It is a disciplined engineering framework that protects programme certainty, cost control, regulatory compliance, and contractual position across complex construction environments.

For large Australian commercial and infrastructure projects, structured BIM coordination services deliver measurable risk reduction. By resolving spatial conflicts digitally before construction begins, projects minimise rework, protect procurement schedules, and maintain installation sequencing integrity. Alignment with the National Construction Code (NCC) further ensures that coordinated systems comply with Australia’s regulatory framework from design through to delivery.

Early engagement with experienced coordination consultants is critical. A properly managed BIM coordination strategy reduces downstream construction exposure, supports prefabrication accuracy, and enhances multidisciplinary collaboration.

To understand our technical capability, governance structure, and delivery experience across Australian projects, visit our About page. For project-specific coordination support or to engage our national team, contact us via our office locations and contact page.

Structured coordination is not an optional enhancement. It is a construction risk management necessity.